Tel: 0531-88785322 88789322

National free service hotline: 400-666-5087

E-mail: 2320073198@qq.com

Website: www.yibogd.com

Factory Address: Industrial Park, Shanghe County, Jinan City, Shandong Province Industry Road 10

Website : en.yibogd.com

Outdoor cable price manufacturers tell you: basic knowledge of optical cable engineering design

Netease mercenary

1 Optical cable line engineering design process

2 Communication line basics Commonly used line equipment introduction Underground entrance room main cable overhead line transfer box pole long-distance optical cable line project main body items consist of optical cable and cable joint box, other items have optical distribution frame (ODF), cable tail Fiber, adapter, galvanized steel strand, hanging wire hoop, cable hoop, hook, concrete cement rod, cable tray, pull iron handle, liner ring, etc.

Cable structure: structure of loose-layer stranded cable

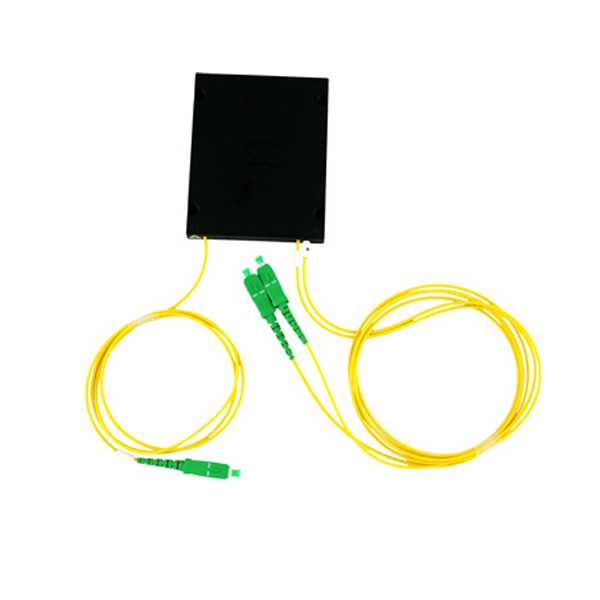

Optical cable single disk ODF, optical junction box

Common line introduction

Direct burial: investment, slow repair, poor scalability

Overhead: Investment province, fast repair, poor security, scalable

Pipeline: large investment, high security and good scalability

Water cable: large investment, poor safety, and expandable

Directly buried

Overhead pole road

Galvanized steel stranded wire, hanging wire hoop, wire hoop, hook, concrete cement rod, cable puller, pull iron handle, backing ring

Pipe section

Various pipes (PVC pipe, silicon core pipe, cement pipe, etc.) are composed of other materials, such as manhole rings, cable brackets, cable trays, water tanks, steel bars and cement.

Introduction of relevant norms, standards and regulations

GB50373-2006 Communication Pipeline and Channel Engineering Design Specification

YD/T5178-2009 Communication Pipeline Manhole and Hand Hole Atlas

YD/T5148-2007 overhead light (electric) cable communication pole road engineering design specification

"Local Communication Line Engineering Design Specification" (YD/T5137-2005)

"Local Communication Line Engineering Acceptance Specification" (YD/T5138-2005);

"SDH Long-distance Optical Cable Transmission System Engineering Design Specification" (YD/T5095-2005);

"Design Specification for Long Distance Communication Optical Cable Plastic Pipeline Engineering" (YD/T5025-2005)

"Code for acceptance of long-distance communication optical cable plastic pipe engineering" (YD5043-2005);

"Design Specification for Long Distance Communication Optical Cable Line Engineering" (YD/T5102-2005);

YD5007-2003 Communication Pipeline and Channel Engineering Design Specification

YDJ 9-90 City Communication Plastic Cable Line Engineering Design Specification

3 Communication line engineering survey

The “survey” in the line engineering design includes two processes of “inspection” and “measurement”.

Generally, large-scale projects can be divided into three stages: “planning survey (feasibility study report)”, “preliminary design survey (preliminary design)” and “on-site measurement (construction map)”.

Survey process for accessing optical cable lines

The site survey of the access cable project involves three main steps: To facilitate understanding, the survey process and key points are simplified as follows:

Pre-investigation period--points: exchange with the construction party (determine the confirmation of access points and programs, data collection);

During the survey - key points: field survey;

Late investigation--points: Reports must be reported to the construction party, and the survey plan and results must be confirmed.

Survey

First, preparation work

1. Personnel organization. The survey team shall be composed of units of design, construction, maintenance, construction, etc. The number of personnel depends on the size of the project.

2. Familiar with research related documents. Understand the project overview and requirements, and clarify the engineering tasks and scope. Such as the nature of the project, size, construction reasons, near and long-term planning, and so on.

3. Collect data. The data collection work of a project will run through the entire process of line survey and design; the main data should be collected before the survey and in the survey. In order to avoid conflicts with other departments or cause unnecessary losses, the relevant units and departments should be investigated and collected in advance to collect relevant information on other construction aspects, and strive for their support and cooperation. Relevant departments are: planning committee, construction committee, telecommunications, railway, transportation, electric power, water conservancy, farmland, meteorology, fuel, metallurgical industry, geology, radio station, military and other departments. For the reconstruction and expansion project, the original engineering materials should also be collected.

4. Develop a survey plan. Based on the design task book and the information collected, a rough plan is drawn up for the project profile. The rough plan can be used as the basis for the development of the survey plan.

5. Preparation for investigation. Different tools can be prepared for different survey tasks. Common general tools include: telescope, range finder, ground resistance tester, compass, tape measure, rope ruler (ground chain), benchmark, carry-on board, tool bag, etc., as well as the forms and papers needed for the survey. Stationery, etc.

Second, survey

1. Routing The routing is based on the requirements of the design specification and the preliminary plan determined in the previous period.

Optical cable and pipeline routing, long-distance lines and local telephone lines have different specific points and requirements. The detailed requirements refer to the following chapters.

2. Site selection According to the relevant provisions of the engineering design task book and design specifications, the branch station, the transfer station and the optical transmission relay station are selected. The specific requirements for site selection are not the same. You can refer to the following chapters separately.

3. When external pipelines and optical cables need to cross railways, highways, important rivers, other pipelines and other relevant important engineering facilities, they should contact the relevant units, and important parts must obtain the written consent of the relevant units. When a contradiction occurs, it should be carefully negotiated to reach a consensus. If the problem is serious, a formal written agreement should be signed.

4. The data compilation is comprehensively summarized according to the situation of on-site investigation, and the following materials are sorted and inspected:

(1) Mark the main route, selected site, important targets and obstacles on the map.

(2) Sort out the distance between the station and other types of data required for design.

(3) Propose the correction scheme for local route and site, and compare the advantages and disadvantages of each scheme.

(4) Draw the relevant drawings for filing and filing with the urban construction department.

(5) Comprehensively summarize the survey situation, report to the construction unit, and listen carefully to further improve the plan.

Measurement

First, preparation before measurement

1. Staffing: According to the scale and difficulty of the measurement, the corresponding personnel are equipped, and the division of labor is clearly defined, and the schedule is customized.

2, tooling: according to the needs of engineering categories and measurement methods, equipped with the required measurement tools. Commonly used tools are: red and white flag (and accessories), theodolite, ruler, rope ruler,

Tape measure, machete, compass, telescope, hoe, hand saw, hand level, umbrella, range finder, drawing supplies, tool bag. In addition, auxiliary materials such as stakes, red and black paint should be prepared.

Second, the line measurement division and work content

Third, finishing the drawings

1. Check the various drawing papers. 2. Organize the registration data, the measurement and prevention data, and the external investigation contact work record. 3. Statistics of cable length and various workloads. After the data is sorted out, the measurement team should conduct a comprehensive systematic summary and focus on the routing and various protection and reinforcement measures.

4 Design of optical cable lines

4.1 Cable routing options

Cable routing principle (ensure that the line is safe, reliable, economical, easy to maintain and construct, choose short route)

4.2 Setting of the station

The setting of the station should be able to meet the current system construction, and consider the convenience of future engineering construction and system expansion and upgrading.

The setting of the station is related to the transmission system and technology at that time. At present, the station is generally set at the technical level of 32x10Gb/s DWDM system. The choice of the station has the distinction of equidistant and unequal distance. In general, the station is set up in an unequal distance to save investment and simplify maintenance.

4.3 Determination of laying method

There are several ways of laying and laying the line.

The buried type is directly buried and the pipeline, wherein the pipeline is further divided into an ordinary pipeline and a long-distance special pipeline. Long-distance routes are generally laid in accordance with their importance; comprehensive consideration of the economics of investment and the terrain, terrain and other factors of the line construction can also be used in overhead mode. In recent years, due to the emergence of some new pipes and construction processes, the cost of pipeline laying has been reduced, and the direct burial of large passages has gradually been eliminated.

When determining the method of laying, consideration should be given to the availability of existing piping.

4.4 Cable (fiber) selection

1. Determination of the capacity of the optical cable:

Cable life is considered for 20 years and is configured on demand.

2. Selection of optical fiber

The types of fibers currently used in the project are mainly G.652 fiber (SMF: standard single mode fiber) and G.655 fiber (NZ-DSF: non-zero dispersion shifted fiber).

G.652D is now commonly used.

Specific indicators can refer to the ITU-T G.652 standard.

FTTH introduced G.657 fiber.

3, optical cable

The optical cable is divided into a layer twist type, a center bundle tube type, a belt shape, a skeleton type, a unit type, a cord type, and the like according to the structure thereof. At present, there are commonly used layered and center bundle tubes.

4.5 Laying Installation Requirements

First, overhead cable laying installation requirements

The overhead cable is secured by a double suspension hoop (or a single suspension hoop).

Second, the pipeline cable installation and installation requirements

Pipeline cables are considered in the form of manual laying, and mechanical traction can also be used when conditions permit.

The inner wall of the long-distance silicon core tube has a small coefficient of friction, and an advanced air flow wearing method can be used.

Third, lead the optical cable

Laying and installation requirements: The upper tube is made of φ100mm galvanized steel pipe, and the inner diameter is 4 pieces of φ32/28mm sub-tubes, and the optical cable is placed in the sub-tube. The sub-tube should be extended as far as 50 cm below the cable suspension wire and tied to the pole. The upper end of the steel pipe is sealed with linseed and self-adhesive materials.

Fourth, intra-office cable

Laying and installation requirements Due to the different conditions of the intra-office optical cable routing stations, some of them are more complicated. Therefore, manual deployment should be adopted.

4.6 Fiber and Cable Connection Requirements

Before construction, the total length of cable laying and the quality requirements of the whole process of fiber transmission should be calculated according to the re-measurement route, and the optical cable should be arranged. The cable should be laid as much as possible to reduce the intermediate joint. After the distribution of the pipe, the cable connector should avoid the traffic crossing; the overhead cable connector should be placed on the pole or about 1 meter beside the pole. At each joint, the cable and the fiber should have a certain margin for future maintenance or Used for secondary connection.

The fiber connection is welded, and the average value of the fusion attenuation of the same fiber in the hop should not exceed 0.08 dB/piece (1310 nm wavelength, OTDR bidirectional test, average).

4.7 Line protection design

First, anti-strong electricity

The local optical cable electrically disconnects the metal components of each single-disc cable at the joint, limiting the accumulation of strong electric influence to the manufacturing length of the single-disc cable (generally 3Km), and the cable line is not grounded, only in each station. Ground. 7/2.2 Steel stranded wire can be regarded as a good conductor for anti-electricity and lightning protection of cable hanging wire, so the hanging wire should be grounded once every 1000 meters.

Second, lightning protection

Under the premise of taking full advantage of the characteristics of optical cable, the following lightning protection measures are proposed:

(1) Except for each station, the metal components of the cable along the line are not grounded.

(2) The metal members of the optical cable are not electrically connected at the joint, and electrical connections are not made between the metal members.

(3) The metal components of the optical cable in the station are connected to each other and connected to the grounding wire.

Third, anti-corrosion, moisture

The cable jacket is made of PE plastic and has good corrosion resistance. The cable core is provided with a moisture-proof layer and is filled with grease, so that in addition to special circumstances, additional anti-corrosion and moisture-proof measures are not considered. However, in order to avoid the local damage of the plastic jacket of the optical cable during the construction process, the hidden danger of moisture penetration into the water is formed, and special attention should be paid to the integrity of the plastic jacket of the optical cable during construction.

Fourth, anti-rat

The hazards of rodents on fiber optic cables occur mostly in pipelines. However, since the pipeline cable is placed in the sub-tube with a small diameter and there are blocking measures at the end, the anti-rat measures are no longer considered.

Five, other protection

For overhead optical cables, if the optical cable is close to objects such as trees, it may be worn. When the optical cable is in contact with other objects, PVC pipes are used for protection. If it is close to the house, apply fire retardant protection. In the case of crossing the power line, insulation should be done.

5 Design of communication pipeline

5.1 Pipe surveying manhole pipe

Site survey

The content and purpose of the site survey are mainly to find out the location of other underground pipelines, the size of the pipeline, the soil quality, the groundwater level, the thickness of the frozen ice layer, the condition of the above-ground buildings, etc., as a reference for construction.

Exploration of above-ground buildings

The survey of above-ground buildings includes the width of roadways and sidewalks, the structure of pavements, the location of street trees, fire hydrants, the robustness of building construction and the standards of underground facilities on the ground.

Underground pipeline exploration

The exploration of underground pipelines is a more complicated and meticulous work and must be taken seriously. The collection of data (such as the location of the power cable, the location of the water supply pipe, the drain pipe and the gas pipe, and the pipe diameter) should be accurate and checked in detail.

There are usually three ways to investigate underground pipelines. One is to measure the plane position according to the ground sign, view the diameter of the pipe from the nearby inspection well, and measure the distance from the pipe top to the ground. If this method is not applicable, the pit exploration method can be used to dig a hole in the existing pipeline plane position, and to find out the buried depth, position and diameter of the pipeline. In one type of listening method, this method can only be applied to underground cables, and the plane position and depth of the cable are monitored.

5.2 Routing and location selection

First, the local telephone pipeline routing

After the bureau has planned to define the line network center and the exchange area boundary, in order to ensure the better implementation of the line network plan, some road pipeline construction plans must be investigated.

The general principles of local pipe routing can be summarized as:

(1) Comply with the long-term planning of underground pipelines and consider making full use of existing pipeline equipment.

(2) Select the street where the telephone line is concentrated to meet the requirements of cable development.

(3) Try not to lay pipes along the boundary of the exchange area, railways, rivers, etc.

(4) The shortest route is selected, and the pipeline is still laid.

(5) Selecting the road with the least obstacles on the ground and underground, and convenient construction

Second, long-distance pipeline routing

(1) The communication pipeline is a part of the local urban construction and the underground communication pipeline network of Changzhou City, and should be matched with the existing pipeline network and its development plan.

(2) Pipes should be built on shaped roads with a large number of optical (electric) cables, short distances, and fewer turns and failures.

(3) It is not advisable to construct pipelines where the planning is not fixed, the road soil has not been compacted, sand and other soils are still unstable, and if necessary, the protection channels can be rebuilt.

(4) Try to choose a location with a lower groundwater level.

Copyrignt © 2019 RENDER All rights reserved . Shandong Yibo Photoelectric Technology Co., Ltd.

鲁ICP备19014903号 Powered by Clouds platform Technical Support: Shengcan Technology