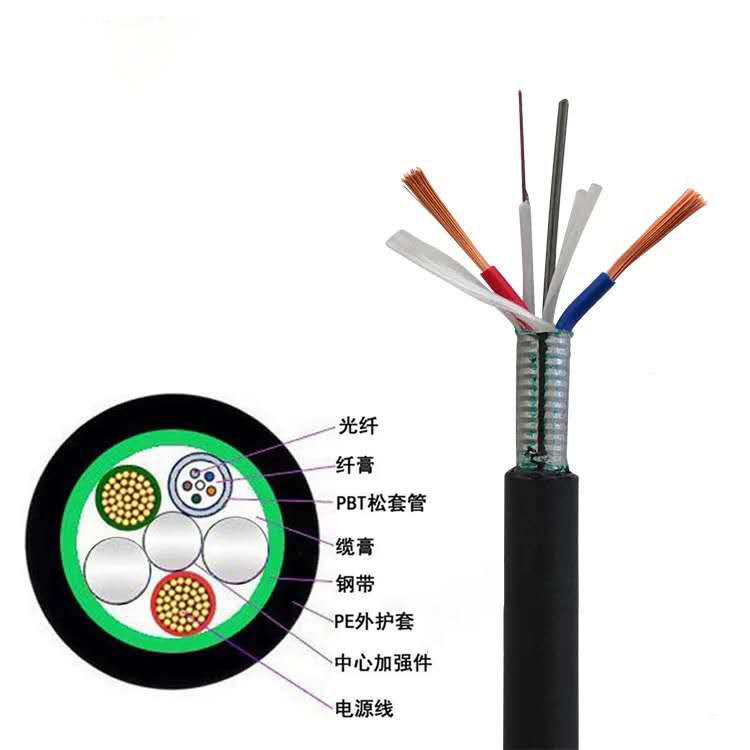

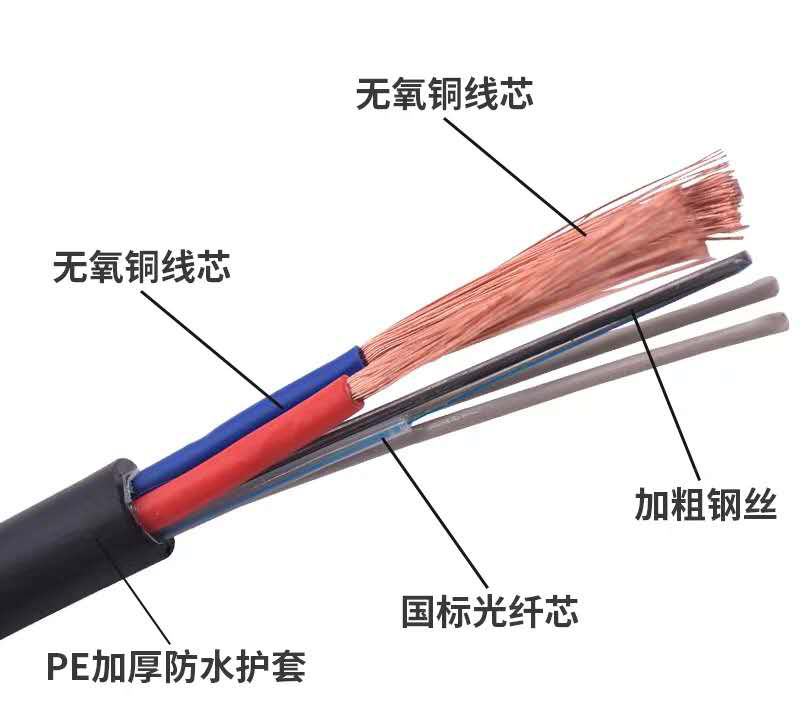

The structure of the layer-twisted photoelectric composite cable is to insert a single-mode or multi-mode optical fiber into a loose tube made of a high modulus plastic filled with a water blocking compound. The center of the core is a metal reinforcing core. For some cores, the metal reinforcing core needs to be extruded with a layer of polyethylene. The loose tube (and the filling rope) is twisted around the center reinforcing core. A circular core with a gap in the core filled with a water-blocking filler. The outer core of the cable is extruded with a layer of polyethylene inner sheath, and the double-coated plastic strip (PSP) is longitudinally wrapped and the polyethylene sheath is cabled.

Features:

l Precise control of the excess length of the fiber ensures that the cable has good tensile and temperature characteristics;

l The loose tube material itself has good hydrolysis resistance and high strength. The tube is filled with special grease to protect the fiber.

l Good pressure resistance and softness;

l PE sheath has good anti-ultraviolet radiation performance and environmental stress crack resistance;

l The following measures are taken to ensure the waterproof performance of the cable:

Single wire center reinforcement, loose tube filled with special fiber paste, 100% cable core filling, double-sided coated steel strip (PSP) to improve the moisture resistance of the cable, a number of copper wires, saving the cost of laying to meet specific needs.

l Operating temperature: -40 ° C to +60 ° C;

l Bending radius: static 10D, dynamic 20D;

l Applicable: pipeline, overhead.

Technical Parameters:

Number of optical cores | Wire specification | Cable diameter | Cable weight | Allowable stretching force | Allowable crushing force |

unit | mm2 | mm | kg/km | Long/short termN | Long/short termN/10cm |

4-12 | 2×1.5 | 11.7 | 170 | 600/1500 | 300/1000 |

4-12 | 2×2.5 | 12.5 | 180 | 600/1500 | 300/1000 |

3, optical cable application

l For temperature and pressure sensing, the structure is bare fiber grease plus PBT oil filling tube plus Kevlar and sheath. This structure sensing cable has high strength, light weight and good water resistance;

l Used in subways, tunnels, firefighting and other industries to conduct temperature sensing to avoid disasters and accidents.